- Home

- Corporate

- Our Activity Areas

- POWER PLANTS OF OUR BUSINESS

- INDUSTRIAL SERVICES

- GENERATORS MAINTENANCE AND REPAIR SERVICES

- TURBINE MAINTENANCE AND REPAIR SERVICES

- Power Plant Rehabilitation and Modernization

- Power Plant Erection, Assembling and Commissioning

- Quality Control of Manufactured Electromechanical Parts at Manufacturer Factory

- Movement of Surplus (Second Hand) Plants to Another Place

- PRODUCTION

- TUĞRAN NEWS

- Bulletin

- Contact

Tuğran Enerji

Sanayi ve Ticaret A.Ş.

T +90 (216) 451 30 31

Email: info@tugranmotor.com.tr

TUĞRAN ENERJİ A.Ş.

Cumhuriyet Mah. Yüzyıl Cad. No:70 Yakacık - Kartal / ISTANBUL

TUĞRAN ENERJİ A.Ş.

INDUSTRIAL SERVICES

Turbine Maintenance and Engineering Services

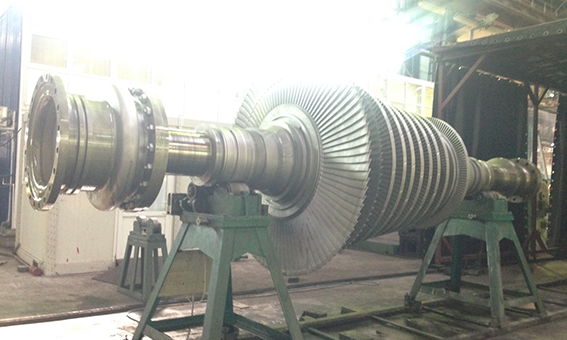

Maintenance and repair of steam turbines

• Disassembling, Maintenance, Assembling of HP, IP , LP Turbines

• Inspection of all parts and reachable area of rotor by NDT(UT, PT, MT, Replica, RT) tests ; discs, blades, couplings, bearing seats for finding cracks, lifetime analyse,

• Dimensional and geometrical checks, measurement of clearances,

• Maintenance of main oil pump, tests and adjustments,

• Maintenance and repair of emergency stop, by-pass and regulation valves,

• Dismantling, maintenance, tests (NDT, bonding) and assembling of turbine bearings,

• Blue paint joint check of white metal and journal surface

• Measurement of lubrication clearances

• Stationary and rotating blades&bandages manufacturing and replacement, NDT tests

• Sand blasting of parts cases, blade carrier rings, diaphragms and NDT tests, welding and corrections

• Manufacturing, replacement of labryhints and machining according to clearances

• Replacement of gaskets (hydrogen and oil seals) with new ones

• Blue paint check of inner and outer cases horizontal joint surfaces and corrections if necessary

• Coupling surface and unconcentricity check, honning the holes and line alignments

• Bolts manufacturing, calibration of holes threads

• Assembling, adjustments, alignments and commissioning

Manufacturing of Steam Turbine Parts

Following parts are manufactured by reverse engineering as original ones; • Manufacturing rotationary and stationary blades, bandages, carrier rings,• Nozzle Manufacturing

• Diaphragms and labyrinths manufacturing

• Shaft manufacturing

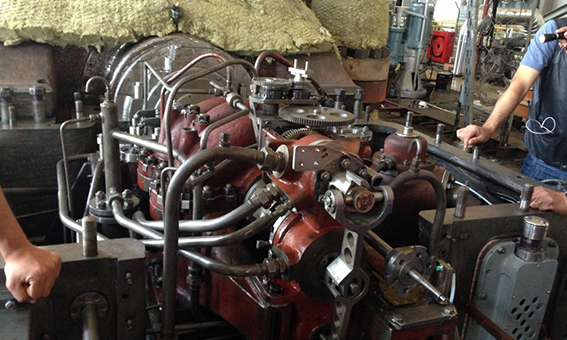

Gas Turbines maintenance, rehabilitation and repairs

• Overhauling of turbine and combustion chambers• Replacement of burners in combustion chambers

• Maintenance and tests of existing burners

• Maintenance and tests of stationary blade rings in turbine

• Dismantling, maintenance, assembling and tests of diffusers

• Dismantling, maintenance repair, assembling and tests of turbine rotor

• Dismantling, cleaning tests and assembling of stationary and rotationary blades of turbine and compressor

• Check of gas lines and maintenance of control valves

• Control and replacement of combustion chamber ceramics

• Maintenance and adjustment of gas and liquid oil stop and regulation valves

• Minor and major overhauls of gas turbines

• Maintenance of air controlers and renew of silencers

• NDT tests of complete rotor, discs, couplings, and other reachable areas (MT, UT, PT, radiographic check), microstructure inspection, surface and inside cracks controls, lifetime analyses

• Diameter measurements of bearing journals, dimentional and geometrical measurement and control of rotor before montage of rotationary blades

• High speed balance and overspeed tests of turbine rotor

• Final machining of new rotor blades after assembling to shaft

• Dismantling the turbine bearings check and maintenance, assembling

• Line alignments

• Replacement of turbine air inlet filters

• Maintenance and teats of compressor blades

• Remedial of rotor shaft bending

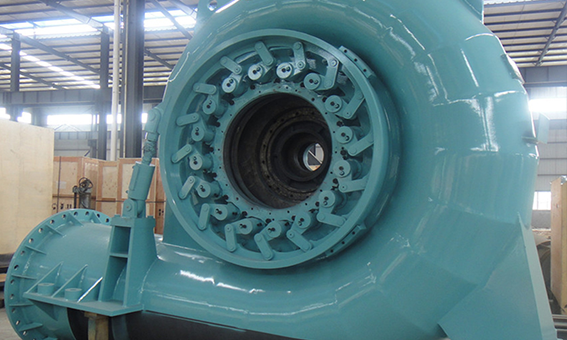

Maintenance and repair of hydro turbines

• Maintenance and repair of horizontal and vertical pelton, Francis and kaplan turbines• Cavitation repair

• Bearings repair, maintenance, remetalling of babbit

• Maintenance and repair of inlet valves

• Maintenance of control oil system, cooling system, filters, governor and regulation system

Turkish

Turkish

English

English